The breeding industry developed fast in industrialization and large-scale today, the hatchery automation assembly line has a broad market prospect, EI chicks processing realized the whole line automation. Operators only need to pull the trolleys, greatly reduce the labor cost, has obvious advantages in market competition, and breakthrough the bottleneck of the industry development.

The transfering &loading unit, turnover &separaton unit, gender identifying unit and immune platform, villi and broken eggshells adsorption, counting and packing unit, and baskets washing machine combined realize the automatic grab and dump of baskets, automatic separation of chicks and eggshells, broken eggshells adsorption, chicks shor-distance transport,gender identification,immune, healthy chicks selection, counting and packing, baskets cleaning and so on,which have already achieved the total automation of hatching and reach the international advanced level.

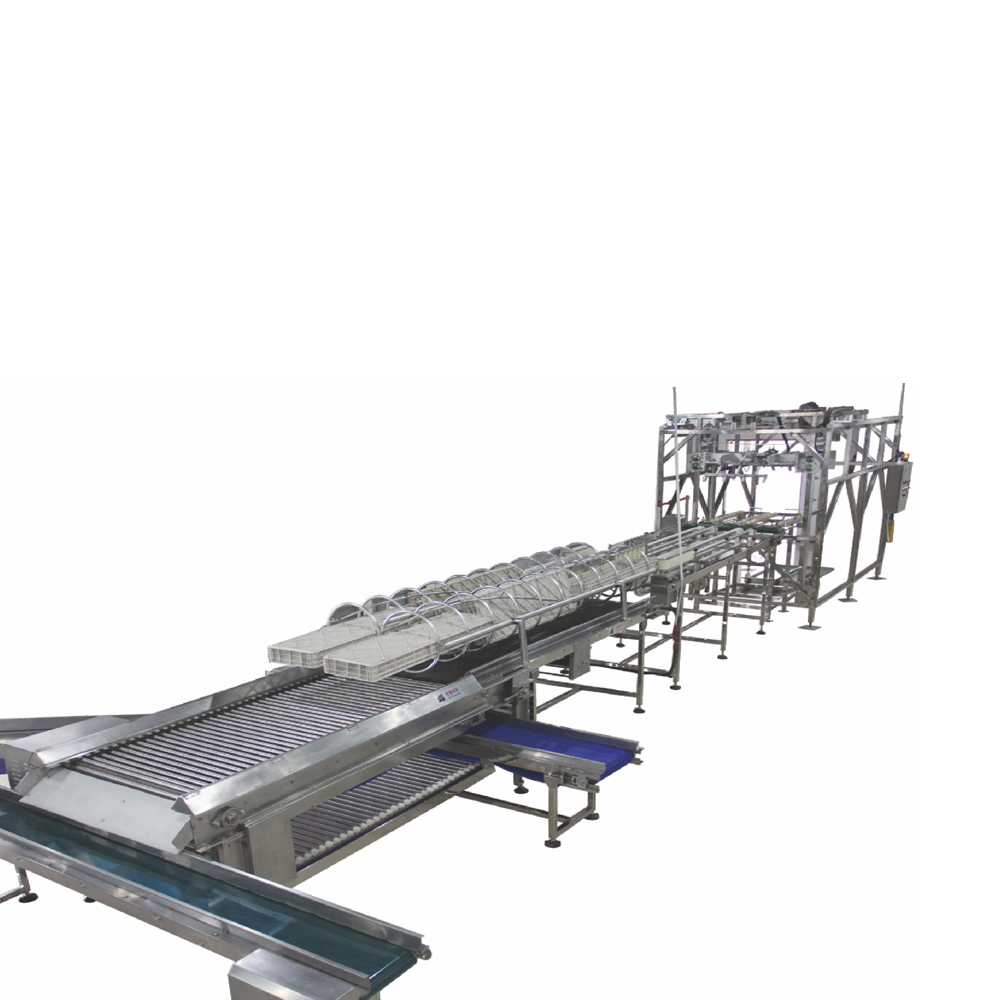

Front-end equipment for chicks processing

Transfering & loading unit mechanically transfered hatching basket in Hatcher to Turnover & separation unit assembly line.Turnover & separation unit automatically empties hatching basket, and separates young chicks and eggshell. The seamless connection of these three modules forms the front-end equipment of young chicks' treatment, the control units are very high degree of automation.

Working procedure

Operator pull out two hatching trolleys from hatcher, push into positioning device of Transfering & loading unit,press the start button, the system automatically transfer two-columns hatching baskets with three-layers to roller table line after detecting the hatching trolley, hatching basket mechanism push baskets into the keel chain conveyor at three times. Baskets emptied automatically after going turnover mechanism, empty batching baskets washing machine for cleaning and disinfection. Young chicks and the egg shell dumping on the conveyor belt are separated in the roller separation unit, and egg shell and unhatched egg are centralized processing delivered into garbage disposal room by conveyor, young chicks be delivered to the next station through chain conveyor for selecting, gender identification, injection and immunization ,counting, and packing and so on.

Front-end equipment for chicks processing

Transfering & loading unit mechanically transfered hatching basket in Hatcher to Turnover & separation unit assembly line.Turnover & separation unit automatically empties hatching basket, and separates young chicks and eggshell. The seamless connection of these three modules forms the front-end equipment of young chicks' treatment, the control units are very high degree of automation.

Working procedure

Operator pull out two hatching trolleys from hatcher, push into positioning device of Transfering & loading unit,press the start button, the system automatically transfer two-columns hatching baskets with three-layers to roller table line after detecting the hatching trolley, hatching basket mechanism push baskets into the keel chain conveyor at three times. Baskets emptied automatically after going turnover mechanism, empty batching baskets washing machine for cleaning and disinfection. Young chicks and the egg shell dumping on the conveyor belt are separated in the roller separation unit, and egg shell and unhatched egg are centralized processing delivered into garbage disposal room by conveyor, young chicks be delivered to the next station through chain conveyor for selecting, gender identification, injection and immunization ,counting, and packing and so on.

Main feature

The front-end line of young chicks handles with 60000 chicks per hour, greatly improve production efficiency, and reduce the workers labor intensity.

Thoroughly improve working conditions for workers.

Reduce the direct contact with the man and the young chicks,avoid pollution and cross infection, and improve the biosecurity standards.