HQ-210 Intelligent electric counter

The Intelligent electric counter is designed for poultry slaughterhouse birds counting, which is high speed and high precision. This product is precisely controlled by fully imported automotive-grade integrated chips, with stable performance, clear display, accurate technology, no data loss after power failure, long-term memory function, easy installation, easy operation, waterproof features, suitable for harsh environments

This product is precisely controlled by fully imported automotive-grade integrated chips, with stable performance, clear display, accurate technology, no data loss after power failure, long-term memory function, easy installation, easy operation, waterproof features, suitable for harsh environments. It is suitable working for poultry and animal processing line, such as chicken, duck, geese, pigs, cattle, sheep, etc.

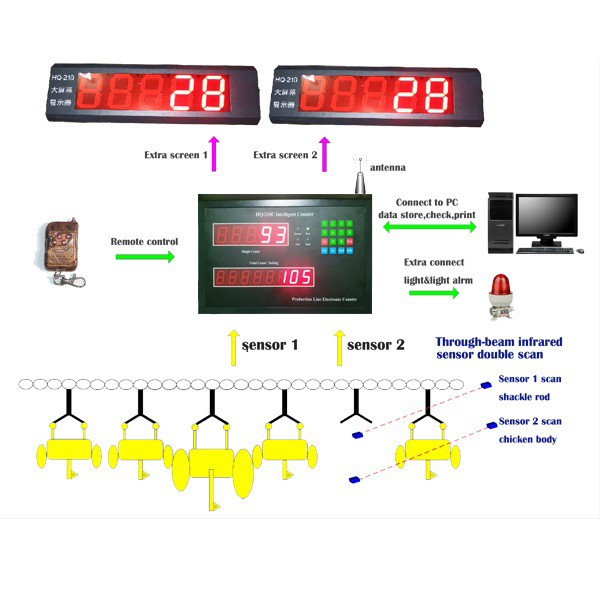

HQ-210J Intelligent electric counter working principle for poultry processing line.

HQ-210J is working with double detecting sensors, which is sensor 1 scan the steel rod of shackle; and sensor 2 scan the poultry body.

☆ If sensor 1 and sensor 2 scan the object at same time, so it takes as one poultry, counting 1.

☆ If sensor 1 scan the steel shackle rod, but sensor 2 doesn’t scan poultry, it takes as empty shackle and counter doesn’t counting.

☆ If sensor 2 scan the poultry, but sensor 1 doesn’t scan steel shackle rod, the counter doesn’t counting.

Function and feature:

1. Solve the problems of poultry different size , swing after hanging the poultry, small gap between each two poultry, and realize high speed and precision counting.

2. The sensor system is water and humidity proof, it is suitable for easy condensing environment.

3. Easy installation and operation. There is no need test, dummy device.

4. Through beam infrared sensor, high intelligent resolution, completely effective to ensure accurate counting

5. Twin window screen: Showing the unit counting and total counting; High brightness LED digital tube, direct view, and clear.

6. The working environmental temperature is from -50 to 80 ℃.

7. Don’t losing counting number when electricity shut down, automatic saving the data before shut down, and recover the status before electricity shut down.

8. It is optional to connect with light&voice alarm, It alarm when the number reach to the target value.

9. The sensoring time is adjustable. The sensor signal is put by photoelectric, the sensoring time can be set from 20 ms to 9.9s.

10. One-click reset; It can be manually pressed on the host to clear the single accumulation with one key; it can also be set to automatic cycle mode, after reaching the set value and delaying for a certain period of time, it will be automatically cleared and the next cycle will be restarted.

11. Remote control: The rest, start, and stop of counter can be realize through wireless remote control.

12. Code protection: The admin can set and amend code; The data resetting and total value clear should put password.

13. Indicator: There is indicating light to show the different working status of counter.

14. Optional connecting with multi. Sets LED screen up to 16 sets, and stimulated show cart delivery, maximum meet client vision requirement.

15. Wireless large screen: The counter is communicating with multi. Sets of wireless large screen and show. (Customize)

16. 485 communication interface: Open communication protocol, easy for improvement, it can connect with PC and sent data to management system or ,PLC /DCS / ERP of plant.

17. PC control and bill printing: Multi. Counters connect to PC central supervision system, or counter equipped delivery management software, store the vehicle number, batch no. product name, delivery time, technical statistics, manager name in PC, query, statistics, printing and report. The query and report can checked by time, batch, and month.

18. Counting and video surveillance integrated system: The counter can connected to video surveillance system, there is no need changing sleeve of surveillance system, and shows counting data at left corner of video, and easy checking historical record.

Over size | 360*220*60mm |

Working voltage | AC 220V +/-10% |

Host machine material | Steel shell, main board is automotive-grade high performance chips |

Working temperature | -50 ℃ - +80 ℃ |

Counting range | Single ” 0-99999; Total: 0-99999999 |

Display number size | Single 4cm word height (red color) Total 3.3cm word height (red color) |

Counting model | Count up/down optional |

Working model | Single birds counting, or continuous counting optional |

Continuous counting resolution | 2-5 pcs |

Power supply consumption | 〈15 W |

Output contact | Start-stop output contact, normally closed; can control secondary control circuits such as belt conveyors Alarm output contact, normally open; can be connected to sound and light alarm devices such as electric bells |

Output contact volume | 220 V/5 passive contact |

Single cumulative clearing method | Manual/remote reset |

Total accumulation clearing method | Password protection, manual reset |

Password protection function | Password can be set and modified by yourself |

Counter host installation method | Desktop placement, bottom fixing, back fixing, back hanging, you can choose by yourself |

Effective distance of sensor to beam detection | Up to 5 meters away. (Up to 15 meters for imported sensors) |

sensor interface | Counters and sensors up to 100 meters away |

Large screen interface / computer interface | 485 communication, can be connected to a computer, the communication protocol is open, and secondary development is possible; Transmission distance 1000 meters |

antenna | Accept the signal from the remote control to realize the start, stop and reset of the counter; The effective distance between the remote control and the counter is up to 80 meters |

Networking function | Each counter can be set to address (1-255) 485 communication interface, with networking function |

(1) Large screen display | 1 line of numbers, display: real-time quantity; 655×230×65mm |

(2) Large screen display | 4 lines of content, showing: customer name, product name, target number, actual number 960mm×672mm×70mm |

Wireless communication distance between counter and computer | 500 meter |